How To Install A Magnehelic Gauge

I figure someone here would be able to explain how to use a Magnehelic Gauge as a Draft Gauge on a Cozy Dual Wall Furnace? What measurement should one. Magnehelic ® gage is connected. Installation is similar to standard gages except that a 4-13/16˝ hole is needed for flush mounting. The medium pressure.

A magnehelic differential pressure gauge is an extremely sensitive diaphragm which responds quickly and effectively to the changes in pressure. The response of this instrument towards the changes in pressure is basically its performance in giving an accurate measurement.Let us check out the features of the measurements that this instrument records: • It measures differential & static pressure in cooling, ventilationand heating or HVAC systems. • The pressure measured with this instrument can either be negative, positive or differential. • Measuring the fan and blower pressure,Room Pressure the furnace draft, pressure drop across orifice plates, air velocity, filter resistance, pressure in fluidic systems or amplifier and the liquid level of bubbler systems. Getting the accurate measurement is a priority but to be bang on accuracy, it is essential to ensure that the instrument is put to function precisely. Implying that we must understand how this instrument works?

How a Magnehelic Differential Pressure Gauge Works? A needs to be levelled and positioned vertically or else the diaphragm starts sagging. This creates shifts in pressure that leads to inaccurate readings.So, while using this instrument make sure to level it right and vertically precise. It is because of the distinct shape of the instrument that reading the measurement needs an eye for detail.

Look straight at the dial to read the pressure that the device shows and not from any other angle. This is because the shape of the lens will distort the readings if you look at the dial from any other angle. This distortion will take place in the form of inaccurate readings which is technically defined as parallax error. Availability of Magnehelic Instruments The Magnehelic instrument is available in a variety of scales that consists of various pressure units which range from Pascal’s and inches of water column to the pounds per square inch. Due to the wide variation in the instruments available, technicians can work on several of these variations. Since technicians are skilled to work on a large variation, there is the need to purchase several variations of the instrument in order to cover a large variety of the systems.

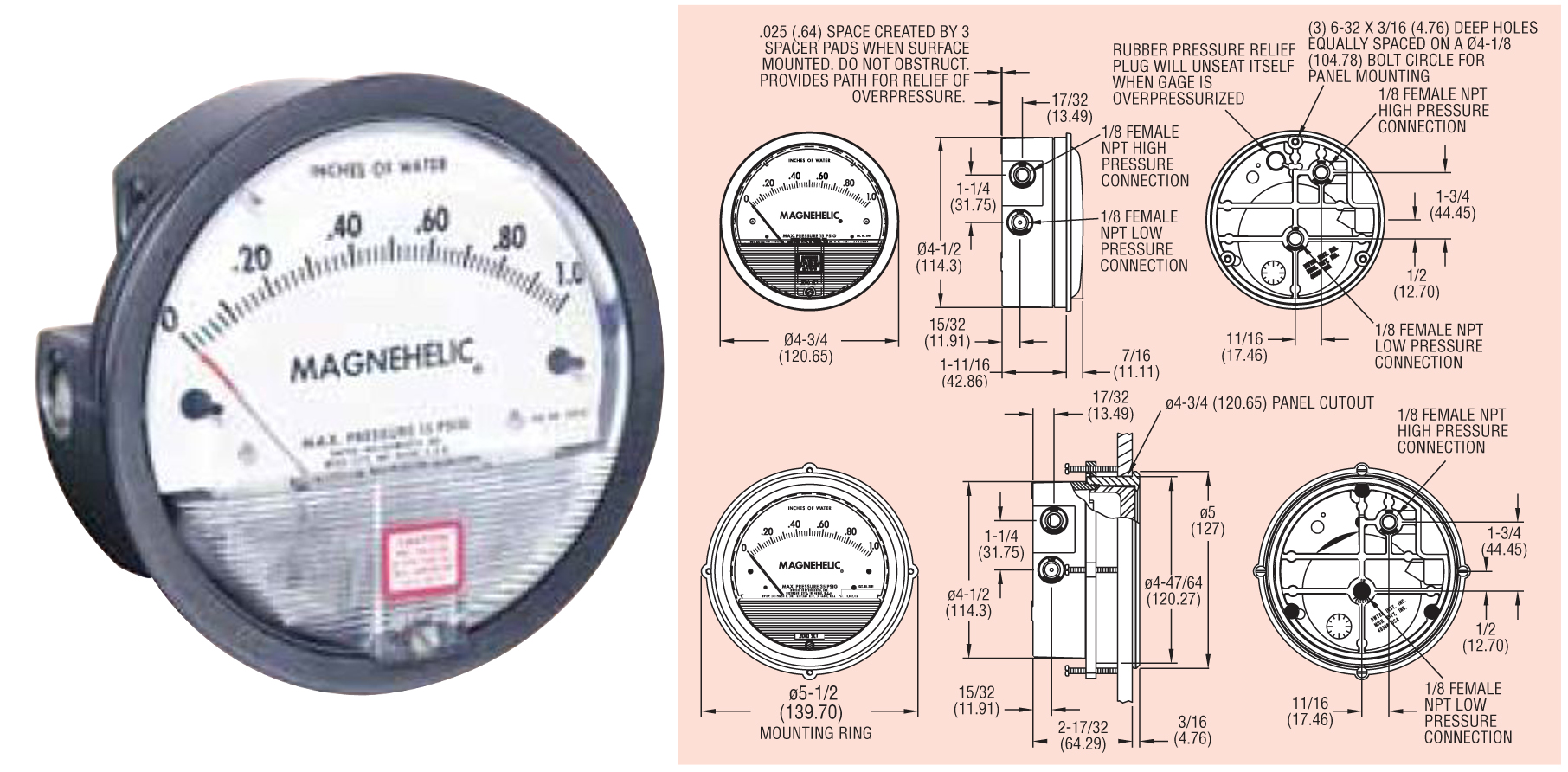

Features of a Magnehelic Differential Pressure Gauge • Housing Material – Aluminium • Service – Compatible gases, air and non-combustible • Finishing – Texture epoxy coat RAL7038 • Wetted Materials – Factory consultation • Pressure Limits – MP option; 35 psig (2.41 bar), 20 in Hg to 15 psig (-0. El Consentido De La Mafia Zip. 677 bar to 1.034 bar)HP option; 80 psig (5.52 bar) • Magnehelic Housing – Bezel with acrylic cover, die cast aluminium case. The exterior is coated with gray to withstand the 168 hour salt spray corrosion test. • Process Connection – 1/8 NPT female brass (SS optional). In the presence of acetylene it is mandatory to use SS • Mounting Orientation – Diaphragm to be kept in a vertical position • Temperature Limits – Low temperature option: -20°F (-28.8°C); 20 to 140°F (-6.67 to 60°C) • Overpressure – The relief plug opens at approximately 25 psig (1.72 bar). Check the overpressure protection note on the catalogue page of the Magnehelic Gauge • Enclosure Rating – IP66. IP65 with the option of OPV (overpressure relief valve).

• Accuracy – ±2% of FS (±3% on -0, -100 Pa, -125 Pa, -10 mm and ±4% on -00, -60 Pa, -6 mm ranges), throughout range at 70°F (21.1°C) • Weight – -1 lb 2 oz (510 g); MP & HP 2 lb 2 oz (963 g) Installation of a Magnehelic Differential Pressure Gauge The front cover of amagnehelic differential pressure gauge is sealed with “O” rings that help in easing the installation processes. The vent holes are further plugged with foam. The extremely high impacting acrylic lens material is resistant to the ultraviolet fogging which keeps the instrument well protected.